Shipbuilding and watercraft construction

The design, manufacture and fit-out of a range of vessels – from small specialised watercraft through to high-speed ferries over 120 m long – takes place at a number of shipyards across Tasmania. Four shipyards are located at a maritime defence industry precinct 20 minutes north of Hobart and one is located just south of the city.

In total, Tasmanian shipyards have over 79 500 m² of undercover production hall space.

Tasmanian companies have extensive experience constructing vessels in aluminium, steel, high-density polyethylene and composites for a wide range of markets and industries including ferries and tourism, aquaculture, maritime security, defence, oil and gas, Antarctic and Southern Ocean operations, and for private vessels.

Tasmania builds high-speed and lightweight catamarans. Our smaller catamarans operate across the world, while our larger wave-piercing catamarans are some of the world’s fastest, most efficient and environmentally clean ships.

Tasmanian companies build tailored boats and specialised watercraft to meet the specific needs of customers and markets. They produce small harbour patrol boats, fast-response vessels and transport craft, coastal landing craft, harbour maintenance craft, rigid-hull inflatable boats and other small vessels for use in inshore areas.

Port development and ship operations

Tasmanian companies and institutions have been involved in the design and development of some of the world’s largest and most complex port and ship operations projects.

Capabilities and services include ship and port modelling, real-time and fast-time maritime simulations, scientific and environmental data collection and analysis, port construction services, and port operations training and software development.

Product and systems manufacturing, engineering and services

Tasmanian companies and institutions provide a range of highly specialised, advanced design and world-leading maritime and marine systems that contribute to vessel design, manufacture, operations and safety for military and commercial markets.

These include:

- accommodation and habitability systems and equipment such as:

- modular accommodation outfitting

- marine anti-glare blinds and screens

- autonomous maritime systems

- automation and control, including ship information management systems

- communication systems and equipment, including antenna systems

- deck and bulkhead equipment

- digital network systems and equipment

- electronic and electrical systems and equipment such as:

- anchoring and chain management systems and mooring equipment

- lightning protection systems

- industrial systems design and upgrade

- internet-of-things, artificial intelligence, smart software and data solutions

- safety and evaluation systems and equipment such as:

- marine evacuation systems and high capacity life rafts

- thermal insulation and passive fire protection systems

- hazardous materials storage solutions

- underwater retrieval, sensing and marking systems

- simulation systems, services, research and consultancy.

Engineering, fabrication and construction capabilities services

Tasmanian companies provide a range of general and high-specification engineering, fabrication and construction services to meet defence maritime requirements.

These include:

- advanced composites

- castings (small, medium and large scale)

- engineering, design (including CAD / CAM and 3D modelling) and prototyping

- hydraulic systems design and manufacturing

- industrial blasting, painting and coating

- laser cutting

- machinery repair and sustainment

- machining

- metal manufacturing, fabrication and construction

- polymer fabrication.

Professional and consultancy services capabilities

A wide range of professional and consultancy services are provided for defence and commercial maritime markets.

These include:

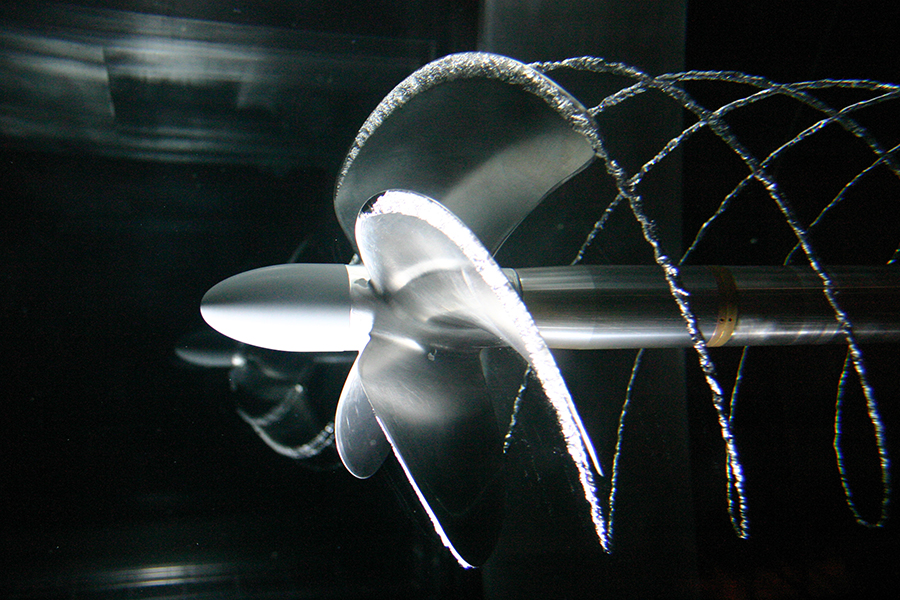

- consultancy services in maritime simulations, offshore and coastal engineering, hydrodynamics testing, cavitation testing, ship and port operations, environmental seabed mapping and marine energy systems

- naval architecture and design services

- environmental analysis, assessment and management services

- hydrographic surveying

- supply of high-speed and offshore support vessels and certified marine crew

- marine safety, emergency and sustainment services

- marine surveying and assessment

- out-of-water vessel repair.

Research, education and training capabilities

Tasmania is home to a number of world-leading maritime and marine research, scientific and educational institutions and organisations, each with distinct capabilities, expertise and facilities.

The Australian Maritime College (AMC) within the University of Tasmania is the national maritime institute specialising in maritime engineering and hydrodynamics, seafaring, and the operations and management of ports and shipping. The AMC consistently earns top annual rankings among the International Association of Maritime Universities.

The AMC offers best-practice vocational education and training and university facilities in maritime operations, maritime engineering, ship operations, port operations, and fabrication, welding and maintenance.

Other significant maritime and marine institutions within Tasmania include the University of Tasmania’s newly established Defence and Maritime Innovation and Design Precinct, the University of Tasmania’s Institute for Marine and Antarctic Studies, Australia’s Integrated Marine Observing System, the Blue Economy Cooperative Research Centre, the Commonwealth Scientific and Industrial Research Organisation (CSIRO) Marine National Facility and the Oceans and Atmosphere Centre, the Australian Antarctic Division and the Centre for Antarctic Remote and Maritime Medicine.

TasTAFE, Tasmania’s public vocational education and training provider, supports the training requirements of major shipbuilders and the broader maritime industry. TasTAFE facilities include the Metal Engineering Training Facility, located in the maritime defence industry precinct at Prince of Wales Bay.

The Tasmanian Minerals, Manufacturing and Energy Council (TMEC) Manufacturing Centre of Excellence provides facilities, training spaces and equipment to develop skills in advanced manufacturing. TMEC facilities used by the shipbuilding industry include a Simulated Work Environment that provides lean manufacturing and continuous improvement training, as well as an Advanced Welding Training Centre with portable virtual reality welding simulators.